Damage Analysis of Plunger Barrel on Performance of Fuel Oil Injection Pump on Generator Ship MT. Vijayanti

DOI:

https://doi.org/10.38035/jafm.v3i4.124Keywords:

Diesel Generator, Plant Maintenance System (PMS), Purifier, Fuel Oil Injection Pump, Bowl and Main Seal RingAbstract

Diesel generator is a machine that can convert mechanical energy into electrical energy, diesel generator has an important role in supporting operational activities on board. The function of the diesel generator is to supply electrical energy, which is comprehensive in the electrical equipment on board. The work process of each part and component on the diesel generator must be properly maintained and checked and maintained so that each part and component of the engine can work optimally according to their respective functions. The purpose of this research is to find out and analyze and find a solution to why the working hours of the plunger barrel component exceed the usage limit and why the maintenance of the fuel oil injection pump pressure area for leaks is still lacking. The research method with research approach uses qualitative methods. Sources of data collected and used in this study were obtained from case studies, problem-solving and qualitative descriptive. Methods of collecting and withdrawing data using observation, interviews, literature study, and documentation. The discussion of this study carried out observations of checking to start from the plant maintenance system (PMS) by the previous crew to the fuel system starting from the fuel tank to the purifier which is directly related to the running of the fuel system at the fuel oil injection pump, as well as checking the fuel injection pump leaking which hinders from performance fuel oil injection is not optimal and makes the fuel pressure drop. The results of the discussion set and reschedule PMS and perform plunger barrel maintenance as well as overhaul the fo purifier and perform maintenance based on working hours. The conclusion is that the plunger barrel working hours exceed the usage limit due to delays in the implementation of PMS and the occurrence of leaks in the fuel oil injection pump area due to: damage to the bowl and main seal ring on the fo purifier, causing the process of separating fuel and dirt from the storage tank to the daily tank into a lot of mixed mud.

References

Bennett, S. (2010). Modern Diesel Technology Diesel Engine. Delmar: Nelson Education, Ltd

Cara kerja plunger ada pompa. (2019, Maret). Retrieved from teknik-otomotif: https://www.teknik-otomotif.com/2019/03/cara-kerja-plunger-pada-pompa- injeksi.html

Lengkap cara kerja mesin diesel 2 tak. (2018, Juli). Retrieve from ilmupedia105.blogspot.com: http://ilmupedia105.blogspot.com/2018/07/lengkap-cara-kerja-mesin-diesel-2- tak.html.

Purifier basic principle working. (2018, February). Retrieved from shipfever.com: https://shipfever.com/purifier-basic-principle-working/

Samlawi, A. K. (2015). Teori Dasar Motor Diesel. Banjarbaru.

Technology/Diesel engine. (n.d.). Retrieved from Britannica.com: https://www.britannica.com/technology/diesel-engine.

Wiranto Arismunandar, K. T. (1975). Motor Diesel Putaran Tinggi. Bandung: P.T. PRADNYA PARAMITA.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish their manuscripts in this journal agree to the following conditions:

- The copyright on each article belongs to the author(s).

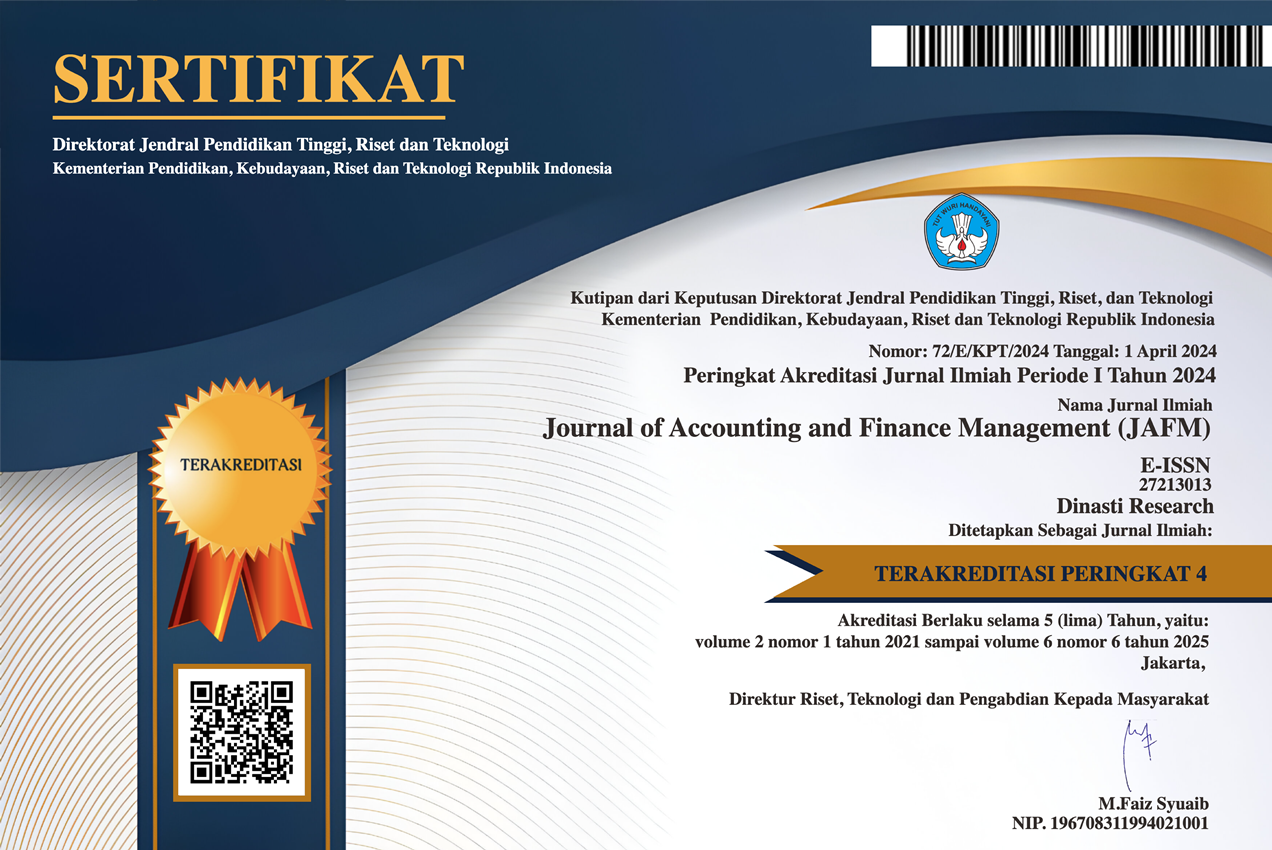

- The author acknowledges that the Journal of Accounting and Finance Management (JAFM) has the right to be the first to publish with a Creative Commons Attribution 4.0 International license (Attribution 4.0 International (CC BY 4.0).

- Authors can submit articles separately, arrange for the non-exclusive distribution of manuscripts that have been published in this journal into other versions (e.g., sent to the author's institutional repository, publication into books, etc.), by acknowledging that the manuscript has been published for the first time in the Journal of Accounting and Finance Management (JAFM).